FF133 Welding Completed

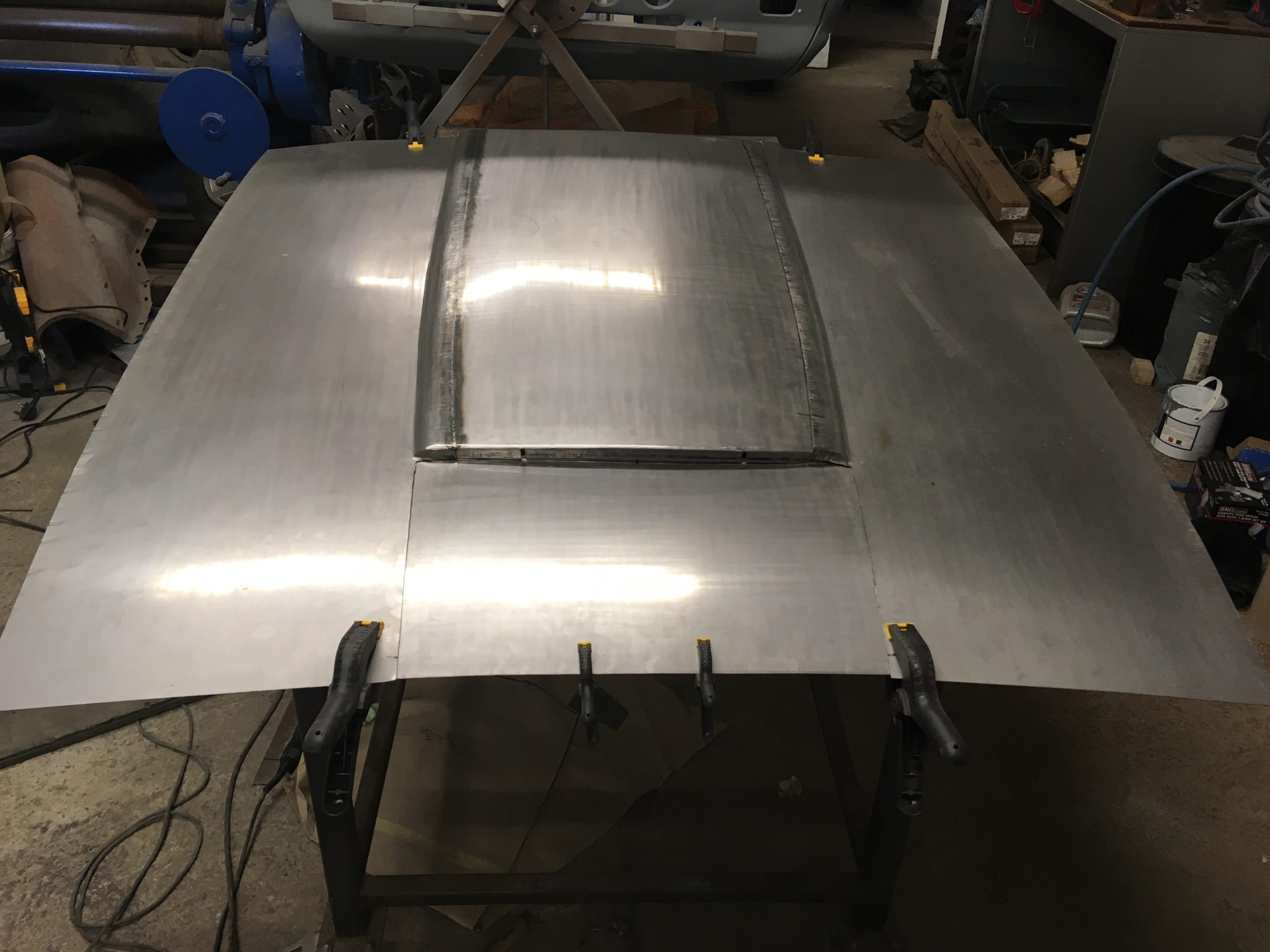

All the metalwork is now complete on FF133 including a handmade bonnet skin.

The car has been taken back to bare metal and now had a protective primer applied as it is booked in for paint in approximately 6 months time.

All the metalwork is now complete on FF133 including a handmade bonnet skin.

The car has been taken back to bare metal and now had a protective primer applied as it is booked in for paint in approximately 6 months time.

FF182 has not made any progress for a while as the customer decided not to continue with the project. Oily Rag Classics have now purchased the car and we are continuing with the restoration.

This car is available to purchase from us as a bespoke restoration project, with the new owner able to decide on the final specification. We will carry on with the restoration in the mean time.

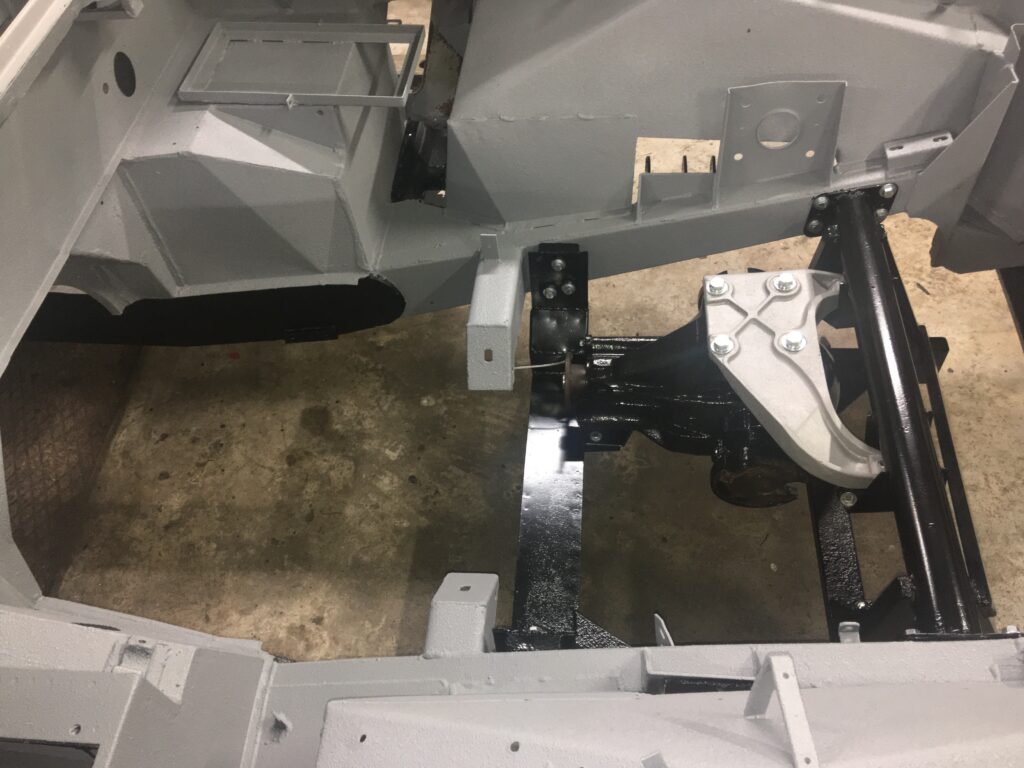

The car has been stripped underneath and in the engine bay and has been painted underneath and a stone chip finish in the engine bay to closely resemble the factory finish. This will be painted black when the body is painted.

The front suspension cage has been refitted with the front diff and the rear springs and axle are also back on the car. It’s great to see some progress with this car after sitting in the corner of the workshop for so long.

FF133 came to me in bits like many cars do, the problem is parts are often broken or missing. I have been slowly buying the missing pieces but as the search for some parts was not successful I decided to make them myself.

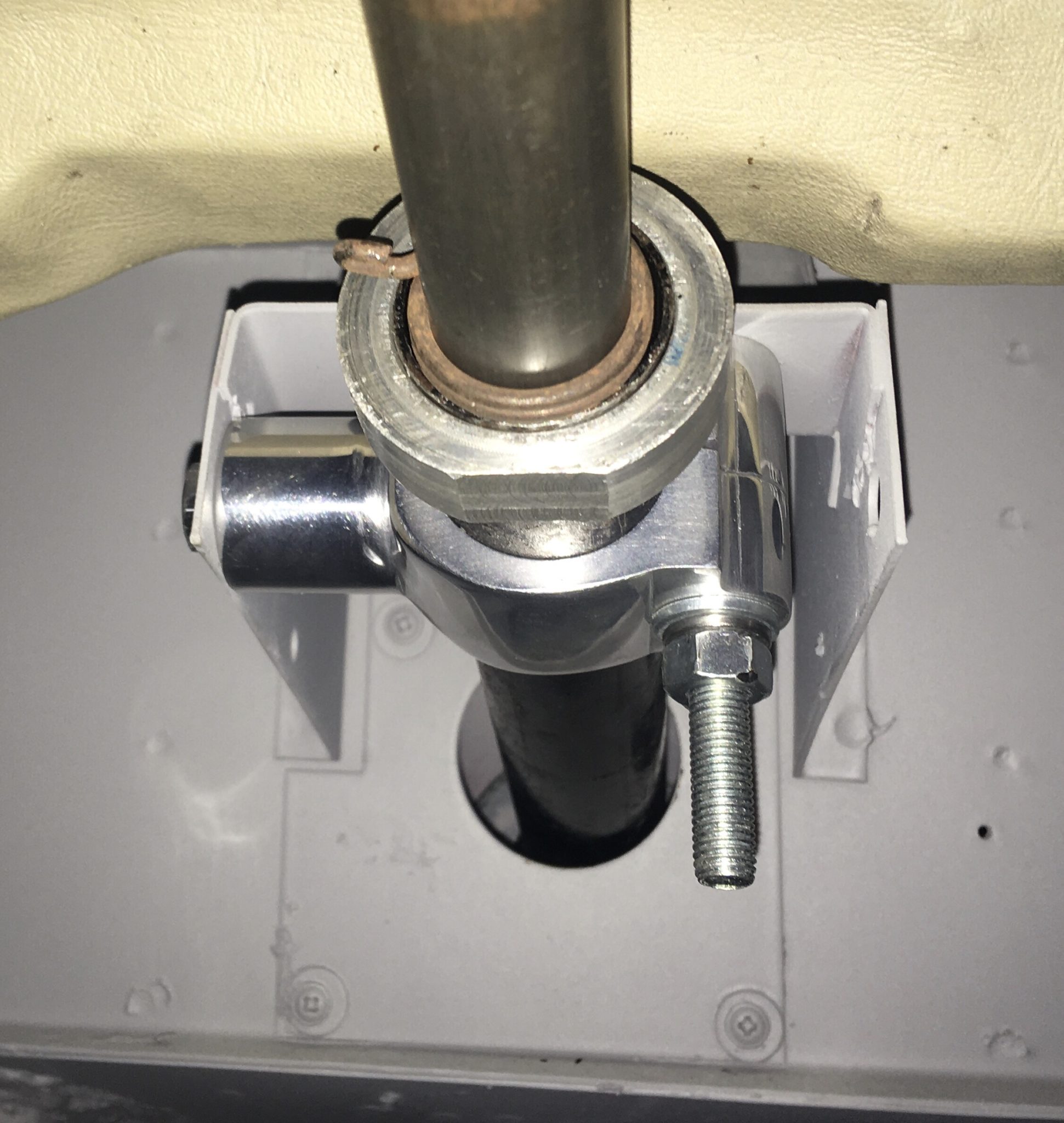

I have machined a few missing pieces but had left the most difficult part until last, originally a cast piece of aluminium to support the steering column under the dash. As casting a single piece would take longer than machining it, I bought a section of aluminium square bar and machined it with a final bit of finishing by hand with a file.

Although not a 100% replica I wanted to keep the basic shape even though it will not be seen once the steering wheel cowl is fitted.

The bonnet on FF133 was solid but had previous bad repairs and would have caused problems when the body goes to the paintshop, so I decided to get a new skin made and fitted to my good frame. The bonnet is now starting to take shape, its great to see craftsman making something using old skills like the English Wheel.

We now have the ability to carry out in house machining having recently purchased a lathe and milling machine.

As soon as the lathe was set up I needed to machine some bushes for FF029 and have a list of other parts to make, some for my FF133 which is missing a few parts which are no longer available.